![]()

Cost Advantage

In the plastic injectino industry, CFD (Computational Fluid Dynamics) is an essential tool to help save thousands of dollars. Virtually verifying injection points positioning allows us to avoid costful mold modifications. Being able to validate the filling capacity of one or many molded parts, from the tool conception stage, will ensure project success.

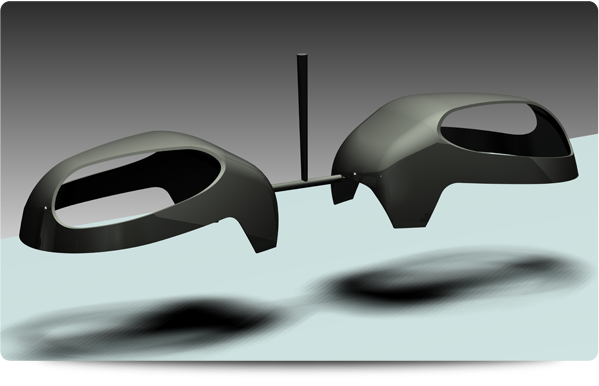

Hot Runner

Mainly in the situation where you have to manufacture a large scale or complex shaped object, CFD may be essential. A hot runner with multiple nozzles can go up to tens of thousands of dollars. Being able to establish nozzle location and quantity to obtain maximum efficiency will result in spending correctly and a lot less.